(~150,000 views * 1 sec each / 3600 secs/hr = 41.7 hours)

|

| from 6:20am today (11/8/11) http://imgur.com/HnoAf |

Meanwhile, I've been exploring the joys of the lasercutter. I found some scrap wood sitting around the lasercutter and etched some of my best friend's art (shout-out to Alice Chung! http://the-crowned.deviantart.com/)

I didn't know what type of wood it was so I approximated:

material, lens, thickness, ppi, power, speed, description

aircraft plywood 2 1/8" 500 15% 80% raster

aircraft plywood 2 .17 300 40% 3% cut ~.17

I also want to make edge-lit signs and found some scrap acrylic. I checked out some real edge-lit signs, the ones used on the newer-style EXIT signs, looking straight up at them, and you can see the individual blips indicating a strip of LEDs. I thought they might have been using a fluorescent tube, which was my other though for lighting -- strip out a discarded scanner's tube and make a lamp ballast for it, then stick it over the acrylic. Todo: buy some nice strips of RGB LEDs. http://www.adafruit.com/blog/2009/09/22/making-an-edge-lit-acrylic-sign/ ~$7: http://ledshoppe.com/Product/led/LE5045.htm

this was .24'' thick acrylic:

ACRYLIC (clear) 2 1/2" 500 80% 50 RASTER, 1/32 inch

ACRYLIC (clear) (tinted) 2 1/4" 500 100% 1.4 cuts through 1/4'' (.21'')

I'm sitting in the media lab shop right now helping a friend, Cathy Wu, make business cards for her imminent plane trip to some conference somewhere (_sigh_ smart people...). I was asleep in my room at 11pm when I heard a loud knocking, which turned out to be a hyper Cathy excited about cutting out business cards with the laser cutter :) I had some anodized aluminum let over from the waterjet clock class / Kevin Rustagi, so there we go.

Giraffe design courtesy of Laura Shumaker, another awesome friend.

Settings used:

METAL ENGRAVE 2 n/a 400 50% 10 (Vector) Engraves into most sheet metals. (incl. anodized Al)to confirm: "my impression was that CO2 bleaches the dye in the anodize coating, while YAG actually penetrates the anodize to etch the aluminum"

The 100 watt lasercutter is definitely not awesome enough to cut this out (we tried full power really slow speed high ppi and it looked to have cut to the same depth as the etching). Maybe the BEAM lasercutter? We settled on using the power shears to cut it out.

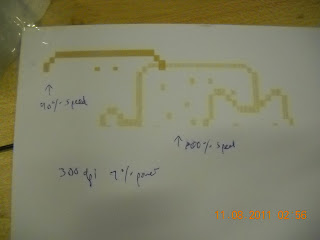

I also learned that one can etch paper without burning it up!

Construction paper 2 0.01'' 500 6% 80% etch; -- @100% speed, 7% min. to etch. @6%, 97% min. speed

|

| thin cardstock -- 1mm thick |

|

| http://www.epiloglaser.com/tl_paper.htm |

Different materials at a glance, with examples (look at the dress under textiles! amazing)

http://lasercuttingshapes.com/page/materials

Everything ever about the Universal 100W CO2 laser and all the possible parameters:

http://www.inlay.com/cnc/laser/index.html

Supplier Acrylics, fluorescent (looks edge-lit without needing lighting):

http://www.usplastic.com/catalog/default.aspx?catid=442&parentcatid=443&clickid=searchresults

Ladyada's examples page:

http://www.adafruit.com/laser/

With more details here:

http://www.ladyada.net/library/laser/settings.html

What people charge for some lasercutting services:

http://www.tree-fox.com/laser-engraved-and-cut-business-card-110.html

And pumpkins! Plastic ones though. We have real ones on hall that I was pondering...

http://www.advancedwj.com/gpage.html1.html

In other news, my surface mount soldering skills have vastly improved with a touch of patience. These all used the: tin one copper pad | tweezer solder the component onto that pad so that it's straight | solder the other pad on | reflow the first pad. This seemed tedious to me in the past, but it actually goes pretty quickly and helps me place my components correctly (darn lack of silkscreening) since I'll go through and tin one pad for all the components.

I also printed tiny-to-be-painted-and-turned-into-earring nyancat:

This is the 3d printer:

Meanwhile in 2.008 we thermoformed for the first time. Here's the thermoform machine:

|

| turned out pretty well, almost none of the webbing we were afraid of. |

| |

| then you use the punch/die to cut out the part you want |

And I shopbot'd a new foam positive. But the silicone negative mold turned out fuzzy :/ with bits of construction foam attached:

Make lots of sacrificial cake until all the foam is melted away? I'm not sure. This silicone will stand up to 400F while the foam melts pretty easily (eg at the hint of a heat gun).

My vending machine coils arrived off of ebay. They definitely look like something I could make by hand.

Also, I learned that ftdi breakout boards are indeed substitutes for ftdi cables. See here for a cool look at what you can do with ftdi:

http://hackaday.com/2009/09/22/introduction-to-ftdi-bitbang-mode/

and some more about ftdi (e.g. vs. avr programmer):

http://www.ladyada.net/learn/breakoutplus/ftdifriend.html

Oh, for 6.131, my final project, some research:

Our normal 6.131 555 pwm generator will not work here. Servo "PWM" signals are very specific -- 2 to 4% duty cycle, 20msec period.

|

| http://www.seattlerobotics.org/encoder/200106/16csscnt.htm |

http://www.hobbyking.com/hobbyking/store/uh_viewItem.asp?idProduct=17143 $5

or implement the circuit:

http://www.societyofrobots.com/robotforum/index.php?topic=13833.0

Also, turns out you can totally do diy soldermask (to mask the circuit traces you don't want to accidentally solder to):

http://retromaster.wordpress.com/pcb-making/ via http://electronics.stackexchange.com/questions/15792/diy-solder-mask-toner-transfer

and a product from seeedstudio:

http://www.seeedstudio.com/wiki/index.php?title=Solder_Mask_Ink

No comments:

Post a Comment